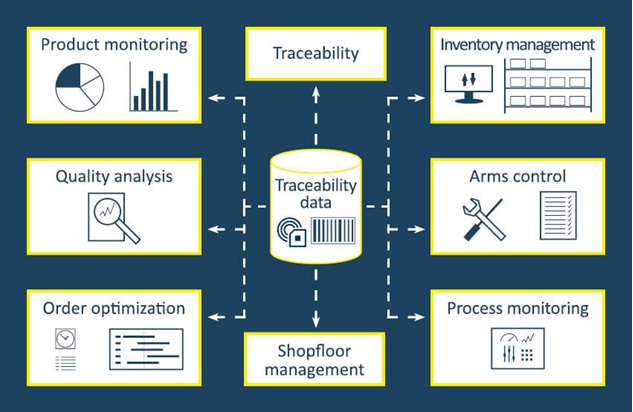

Industry 4.0 marks the integration of advanced digital technologies into manufacturing and industrial processes, enabling the creation of "smart factories“. Manufacturing is driven by advancements in automation, data exchange, the Internet of Things (IoT), artificial intelligence (AI), robotics, and cloud computing. One key aspect of Industry 4.0 is its focus on data collection, monitoring, and analysis in real-time, which is achieved through technologies like Datalogging and Traceability applications (Track and Trace). This application is a key component, which leverage these advanced technologies to provide end-to-end visibility and control over the production and supply chain processes. These applications are particularly vital in all the industries such as pharmaceuticals, food and beverages, automotive, and electronics, where precise tracking is necessary for compliance, safety, and quality assurance.